Wilkat

Guitars :

About Us / Privacy Policy |

Guitars | Basses |

Wilkat's Guitar Tips | Parts

| Links | Contact Us

Wilkat's Help Tips © 2001What can I do to improve the performance of my tremolo -- what's going on?

Boy, this a common problem. One thing or another comes up, whether it's tuning, or up and down action, intonation, saddle height , etc. So let's look at some things and see what can be done about them:

Examine springs first (assuming that your nut is not binding the strings, or you have a locking nut):

Most whammy bars have 2 or more extension springs connected at the rear of the tremolo, to a spring retainer (often called a "claw") attached to the guitar's body. Frankly, I don't feel that 2 springs are enough and prefer at least a minimum of 3 to provide proper action. If you use strings lighter than 0.009 - 0.042" (which most players don't), then 2 springs might work. Of course this depends on the strength of the springs (they do vary), and, how well all the other components are set up on your guitar.

NOTE: Consult a skilled luthier if you are not confident in your ability to assess ,replace, or repair your instrument's tremolo unit. Some replacements require modifications (such as body routing), and may be risky for inexperienced individuals.Considering that there is a fairly strong pulling force from the guitar's strings, the springs need to be adjusted to a suitable tension to bring the bridge assembly back to its neutral position (and hopefully back in tune -- right?). Bear in mind that conventional tremolo units were designed to rest back and sit flat on top of the body when they return to this neutral position. So spring set up is a critical consideration.WARNING: Do not attempt to remove extension springs without wearing safety glasses, or without first de-tuning the guitar, and loosening the claw retaining screws. Failure to heed this warning could result in serious injuries to hands, face or eyes. The use of a special hooked tool is also recommended (don't use conventional pliers, unless all tension is released)

Regardless of whether you have an original style tremolo, or a more contemporary Floyd Rose 1 (or Floyd licensed) style locking design, the springs are vital to the proper operation of tremolo units. If you are using heavier strings (and still using standard A440 tuning), you may need to add one or more springs to the assembly, or you may want to try adding a device such as the "Trem-Setter" from "Hipshot". The "Trem-Setter" is a tremolo stabilizer that fits into the center of back cavity of the guitar, and adds compression spring force to the unit, to help return the strings back to correct pitch. It won't compensate for a broken string(s), and it's not 100% perfect, but it will help considerably. This device will also eliminate tremolo wobble (which can create a warbling effect when striking individual strings). Some players use this as an effect, while others do not even notice it.I won't kid you here, to obtain the best spring action, you will have to experiment a bit. You can start by using the claw retaining screws to increase or decrease the spring force applied to the unit. You should do this with the guitar tuned to pitch (in the tuning that you normally use), and test the action each time (re-tuning as necessary for each adjustment). Don't do this with a fresh set of strings, unless they have been stretched out a bit, and are remaining stable prior to use of the tremolo.

Now if it seems to be working better, or tuning problems have diminished, let's move on.

Binding Nut, or string tees:

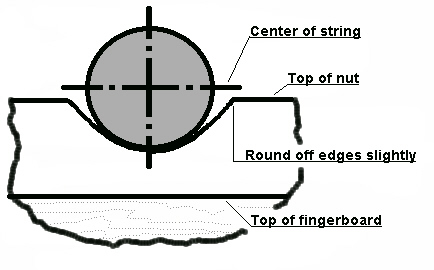

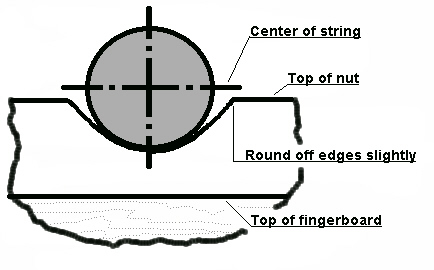

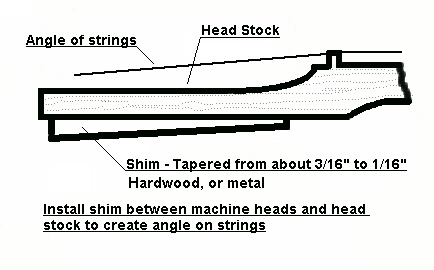

This is a common problem. Many string nuts will not have the slots properly filed to allow the strings to slide freely back and forth, and combined with the grip and friction of certain types of string tees, you can expect the guitar to go out of tune -- especially if you've just completed a major dive bomb! So, what do you do? Well, the nut needs to be filed out slightly larger than the string diameter, and rounded in profile. SEE FIGURE No. 1 If the slot is rectangular and tight, the string will bind -- especially if it's deeper than the string diameter. If you have "old-style" string tees (usually made of bent metal), these will cut into the edge of the string and cause undesirable friction (as well as occasional string breakage). Fortunately, string tees can be replaced with roller types, graphite material, or eliminated altogether by using stepped tuning machine heads, or an angled shim plate installed under the machine heads at the rear of the head stock. This last solution is one of the best, as long as the strings don't pop out of the nut when plucked. SEE FIGURE No. 2

Figure No. 1

Figure No. 2

Still have a problem? Let's check if the saddles are okay:This applies to units with regular saddles only: Check for wear grooves in the top of the saddles. While this is not a major problem, you don't want a slot that's catching the string and preventing free movement of the string over the saddle. If filing doesn't do the trick, replace the worn saddles with new ones. There are a number of choices, including "Graphtec" which work quite well, and help to eliminate string breakage. The material is hard and slippery, making it a good alternative. If you already have roller saddles, you need to check these for smooth operation as well. Clean, lubricate (use a Teflon based lubricant) and / or replace as necessary.

NOTE:A related problem can occur at the string holes that pass through the bridge plate. The edges of these holes can often be sharp, causing binding and / or string breakage. A simple remedy is to file the edge of the holes (countersinking and de-burring is even better). Alternatively, some players install small pieces of electrical insulation tubing (removed from electrical wire) over the strings, and slide them down to fit just inside the tops of the holes. These soften the edge of the hole and allow the strings to slide through them. Of course you'll need to change them as they wear out.

Locking Tremolos:The babies have a few quirks of their own, and the single biggest problem (other than correct spring set up) will be related to slipping clamps or difficulty adjusting intonation. As the ball end of the strings must be cut and removed, the saddle clamps must tighten down firmly to grip the string. If the clamps don't hold, you can try grinding the contact edge down a bit, or simply replace them with new ones.

Before setting up springs on this type of bridge, loosen the locking nut, then loosen or tighten the spring claw's retaining screws as required to level the bridge with the body. This is where you'll determine if you need to add or remove any springs.

Next set the height of the of the bridge (using the two adjusting screws mounted into the body) for the action you desire. This can be checked at the 12th fret (normal settings range between 1/6" and 3/32") by measuring the distance between the top of the fret and the bottom of the strings. Use a feeler gauge or any piece of wood, plastic, or metal of the correct thickness -- you'll know it's correct when there is only the slightest drag on the gauge when you slide it between them.

NOTE:If after setting the action height of the strings, you experience a lot of buzzing and fret contact, you may need to adjust your truss rod, or have your frets redressed (see my tips on neck and truss rods). For those of you interested in Eddie Van Halen's tapping technique, you'll want the action on the lower side, but not too low, as it makes string bending difficult, since you won't be able to get the balls of your fingers under the strings, so to speak.Roller Nuts:Intonation:To adjust your locking saddles for intonation, you will need to de-tune the string if you want to pull a saddle back, since the string tension pulls it forward when you loosen the lock down screw. There are also tools you can purchase to assist with these adjustments, and eliminate de-tuning. Or you can make your own device to tilt and retain the bridge in a forward position to reduce string tension, which will allow you to make desired adjustments in either direction.

Naturally these rollers need to be functioning well, or your tuning problems will remain. Lubrication (use a Teflon based lubricant) may help, but if any corrosion of dirt is present...well, you know what's required. Wear is also a factor again, and nothing lasts forever. If the nut is new, check the string slots are large enough not to cause any binding. If this does happen (it is rare), take it back to your repair guy, or try filing it out with a piece of diamond strip (similar to the stuff dentists use between your teeth).

Sometimes the problem can be due to alignment. Try loosening the screws that mount the unit, and allowing the tension of the strings to align the nut, and then re-tighten the screws. If the nut needs to be raised, install a thin metal shim(s) underneath. Shims can be purchased from a number of places and you can also try your local garage if your music shop can't help you out.1. Note: Floyd Rose, Graphtec, Hipshot, Teflon, and Trem-Setter are recognized brands of the respective manufacturers, and are not affiliated with Wilkat Guitars in any way.